[ad_1]

Batteries symbolize almost one third of the whole value of a typical EV, and there’s a push to get that down to twenty% or much less by the tip of this decade. In an effort to decrease prices and speed up manufacturing, the EV trade has been trying to find methods to make the meeting course of extra environment friendly and to lower the time it takes to create a battery meeting line.

New highly-automated battery meeting strains often take months to develop. Can that be accelerated?

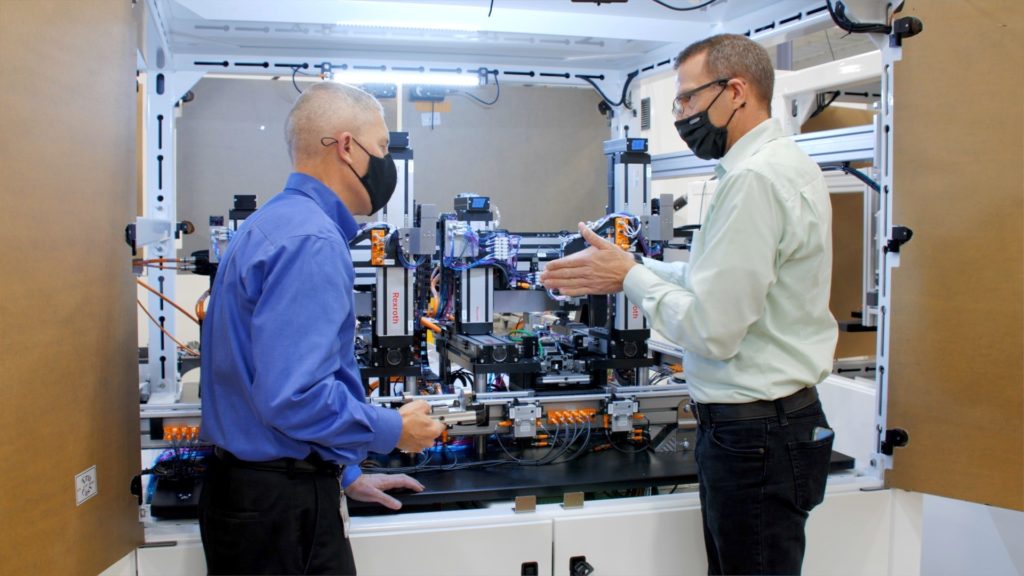

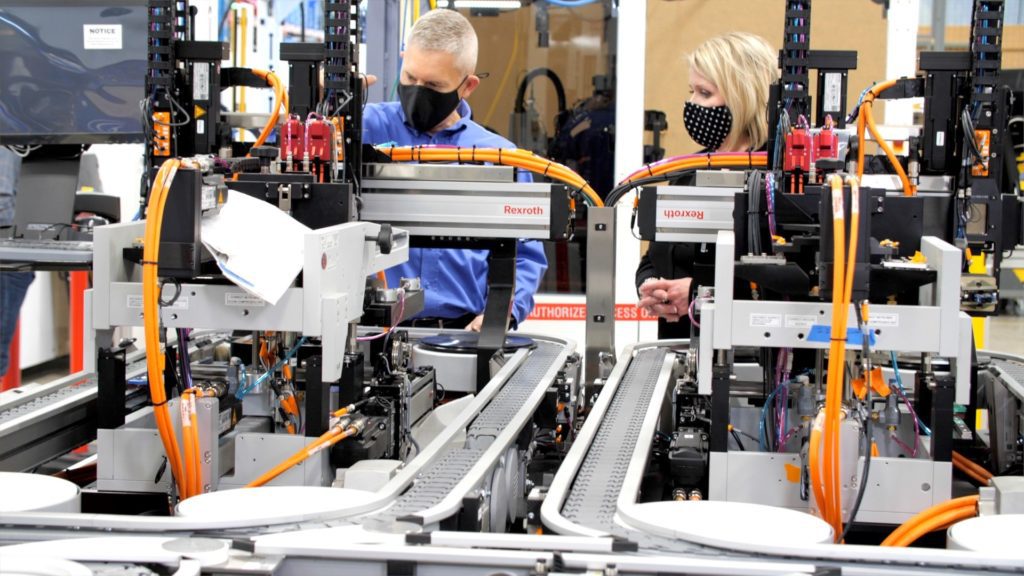

In 2020, precision automation firm DWFritz wanted to develop a posh battery manufacturing line for a number one North American battery producer. The necessities included excessive speeds, a good footprint and an accelerated growth time.

Contemplating the complexity of the venture and the quick growth time, DWFritz determined to kind a strategic partnership with automation provider Bosch Rexroth. Collectively, the 2 corporations operated in a concurrent engineering setting, permitting for fast design iteration and accelerated execution.

“Prior to now, we’d have used a number of totally different suppliers,” defined DWFritz President Mukesh Dulani, “however simply to begin the collaboration between totally different suppliers, on this case, would have taken us at the least 10 to fifteen weeks. For this venture, we solely had 12 weeks of design and engineering time and eight weeks for procurement, so we needed to work with a associate like Bosch Rexroth who may provide the know-how and the engineering help for us to achieve success.”

Irrespective of the cell dimension or kind issue, battery manufacturing is a posh, multistep course of that brings collectively dissimilar supplies to kind the battery’s cathode and anode, then combines them with the insulator right into a completed bundle.

“The road needed to function at very excessive speeds,” stated DWFritz VP of Gross sales Chris Povich. “Area was additionally a problem. Though the road is greater than 100 ft lengthy, it needed to be designed to suit into a really tight footprint. And the movement platform needed to deal with very strong motion-control calls for—one system alone had in extra of fifty axes of movement.”

Collectively, the 2 companions say they managed to create a brand new battery manufacturing line that met the shopper’s necessities and set a brand new benchmark for constructing out manufacturing capability.

To be taught some ideas for creating new manufacturing strains rapidly, Charged not too long ago chatted with Bosch Rexroth’s Mark Ziencina.

Charged: With all the brand new exercise and incentives for native manufacturing in EV manufacturing, demand have to be fairly excessive on your automation experience.

Mark Ziencina: The demand is completely unbelievable. I’m the Vertical Supervisor for Battery and EV at Bosch Rexroth, the automation division of Bosch. I’ve 28 years of manufacturing unit automation expertise in parts and capital gear, and what we’re experiencing now could be via the roof. Our group focuses on options for the battery and EV segments, drawing from our previous expertise with battery know-how and dealing with quite a lot of companions and prospects within the battery and EV markets.

The problem is to maintain up with the demand, and I’m not even speaking concerning the chip shortages and different provide chain points. Everybody agrees that globally, this market goes to be rising at a few 23% compound annual progress fee. Nonetheless, in North America, we see it rising quite a bit sooner than this, as a result of we’re attempting to meet up with China and different Asian international locations who jumped into the market early.

With all of the incentives and new necessities, in addition to all the cash pouring into the EV market, all people wants gear now. Everyone needs batteries. All of them need it on the identical time. So, it’s an excellent downside to have, and with sufficient expertise you possibly can discover ways to get it finished with obtainable assets.

Tip #1: Restrict the variety of strategic companions and suppliers to kind a small group with expertise working in a concurrent engineering setting to permit for fast design iteration and accelerated venture execution.

Charged: Rexroth not too long ago revealed a case examine about its partnership with DWFritz, detailing the way you have been capable of minimize time to implementation for brand spanking new cell manufacturing. What do you suppose are crucial tricks to speed up time to market?

Mark Ziencina: DWFritz was on the lookout for an automation provider for that cell venture that had all the varied options that they wanted, resembling materials switch conveyors, Cartesian programs, and linear actuators that had excessive precision, excessive reliability, and the power to work in cell meeting environments. They have been additionally seeking to execute the venture in a really quick timeframe, versus the usual 12-month execution time.

They selected us, and we turned an extension of their engineering division. Our functions engineers labored side-by-side with their design engineers to shrink the design time via concurrent engineering, a number of iterations, and plenty of backwards and forwards.

For all of those producers, time to market is vital proper now. Partnering with the precise gear builder and the precise automation provider will assist to fulfill these targets, versus managing a basket of various suppliers who should not have the holistic view of the venture and should or might not have the depth of expertise in these functions and processes.

On this venture, a very digital growth setting enabled the staff to create a digital twin of the communication platform between Manufacturing Execution System (MES), the software program that runs manufacturing operations in a manufacturing unit, and automation controllers, saving an unlimited period of time.

Tip #2: Use a digital twin design that means that you can check the programs whilst you’re ready for the {hardware} to reach and be put in.

Charged: How did the footprint necessities of the manufacturing line have an effect on the event time?

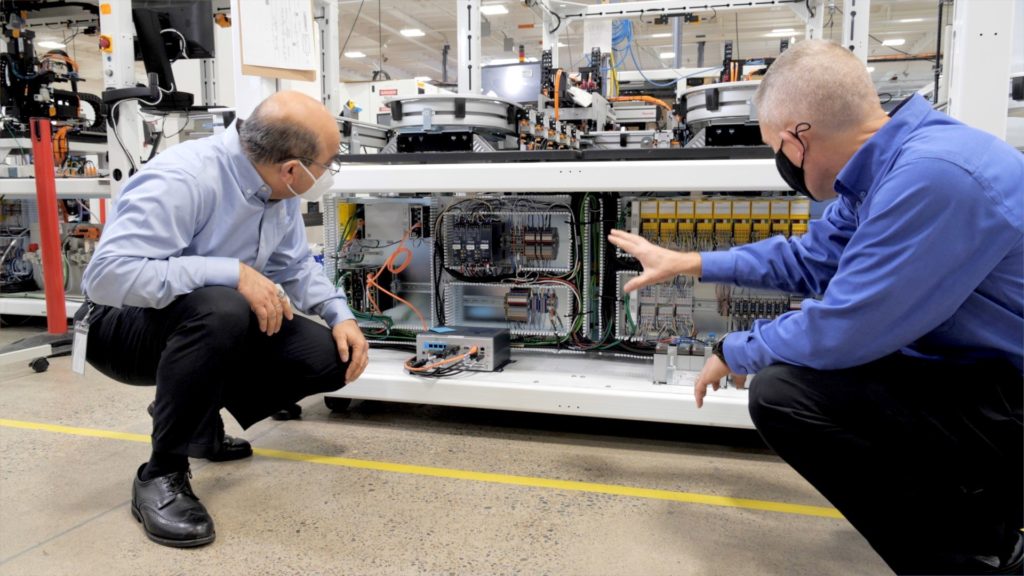

Mark Ziencina: Small footprints can create plenty of challenges that delay design time if the staff doesn’t have the precise expertise. For instance, we used our MTpro structure software program to design conveyors that match into the tight machine footprint and in addition offered the machine-to-machine connection. In some cases, the machine was so jammed with automation—40 to 50 axes of movement in a single body—that there was not sufficient area for a management enclosure to suit all the drives. So, we went with our cabinet-less know-how, which has motors with onboard servo drives, to get rid of the necessity for an enormous field stuffed with servos. The whole lot was distributed all through, which facilitated a extra compact system.

Tip #3: Use an open machine management structure that permits real-time information entry and machine-to-machine communication. This retains all the manufacturing modules in sync and permits operators to watch and management the processes.

Charged: By way of size of the initiatives, what has been the historic growth time for the standard cell line, and what’s the trade pushing in the direction of now?

Mark Ziencina: Relying on the complexity of the venture, sometimes, it was 12 to 14 months to execute a whole line, perhaps a 12 months and a half. Now everybody needs to shrink this down to six to eight months or much less. So the problem is, what can we pull from our previous expertise? What modules and options do we’ve got in our product portfolio that would shrink that design time?

We work on the design aspect as effectively to dump that from the client’s and the producer’s plates. Drawing from our information of cell, module and pack meeting functions, we select options, customise them for the actual product, and shrink that down.

We additionally pool all the uncooked supplies required for our merchandise. We are able to carefully estimate what number of conveyors, for instance, will probably be required for a venture and have them in inventory so we’re not ready on components. So, whereas the design continues to be ongoing, we deliver within the supplies, after which as quickly because the design is full, we will begin sending the ultimate drawings to the manufacturing ground. We do every little thing we will to shrink the design window and the manufacturing execution window by working very carefully with the client.

Tip #4: Work with automation and gear suppliers throughout the product design stage to handle the delicate design particulars that have an effect on the meeting growth course of.

Charged: What are the most typical materials bottlenecks that sometimes delay a venture?

Mark Ziencina:The whole lot is in brief provide—even small issues like T-nuts for aluminum framing. However mostly, it’s the chip scarcity that’s actually impacting all of the automation suppliers. Lead instances on motor controllers will be 12 months or extra. Worldwide, there isn’t a manufacturing sector that’s remoted from the chip scarcity. Getting ready, planning forward, and reserving that capability forward of time is vital, as a result of it may well actually impression the set up and ramp up of those new strains and new capability.

Tip #5: Select suppliers which can be well-versed in a number of open-protocol applied sciences and customizable off-the-shelf modules. This permits customers to write down their very own application-specific modules, avoids the necessity to design every little thing from scratch, and supplies the power to reuse the modules in future product strains.

Charged: What different components are vital to guarantee a profitable execution?

Mark Ziencina: It’s actually vital to choose respected suppliers which have a world footprint and a neighborhood presence, plus expertise within the battery manufacturing area. Moreover, expertise with standardization to open protocols is vital as a result of you must deliver many options beneath the identical umbrella. This assures compatibility with out tying you to 1 explicit provider.

There are such a lot of producers with totally different platforms for management architectures, and each producer tries to lock their prospects into their particular ecosystem. We went immediately towards that with our ctrlX open structure controller design, for instance, which will be programmed in any of the widespread languages. It’s appropriate with anybody’s merchandise. It contains apps that customers can write themselves, so that they’re not locked right into a sure programming setting. You don’t have to seek out specialists who know a particular language or growth platform—you will get programmers to program in Python, C/C++, Java, or no matter they like, to get your entire automation executed. Our controls immediately talk all the best way as much as the MES. It’s vital to choose the precise structure and standardize so that you don’t should help and inventory plenty of totally different merchandise.

Tip #6: Use Business 4.0 know-how resembling sensible sensors, imaginative and prescient algorithms and part monitoring programs to carry out inspections all through the meeting course of. This helps to pinpoint problematic areas and supplies upstream suggestions that may result in manufacturing line adjustments to account for incoming materials variability, precision meeting tolerances and high-throughput calls for.

Study extra

Contemplating the extent of present efforts to ramp up EV manufacturing capabilities and supply battery parts made in North America, we will count on to see plenty of producers attempting to fast-track their meeting strains. They might need to take a lesson from the DWFritz/Bosch Rexoth partnership.

These two corporations not too long ago introduced finally 12 months’s Charged Digital Convention on EV Engineering. To be taught extra concerning the venture, test out the webinar recording.

This text appeared in Challenge 62: Oct-Dec 2022 – Subscribe now.

[ad_2]