[ad_1]

Marposs provides a brand new system for checking pouch cell battery welds

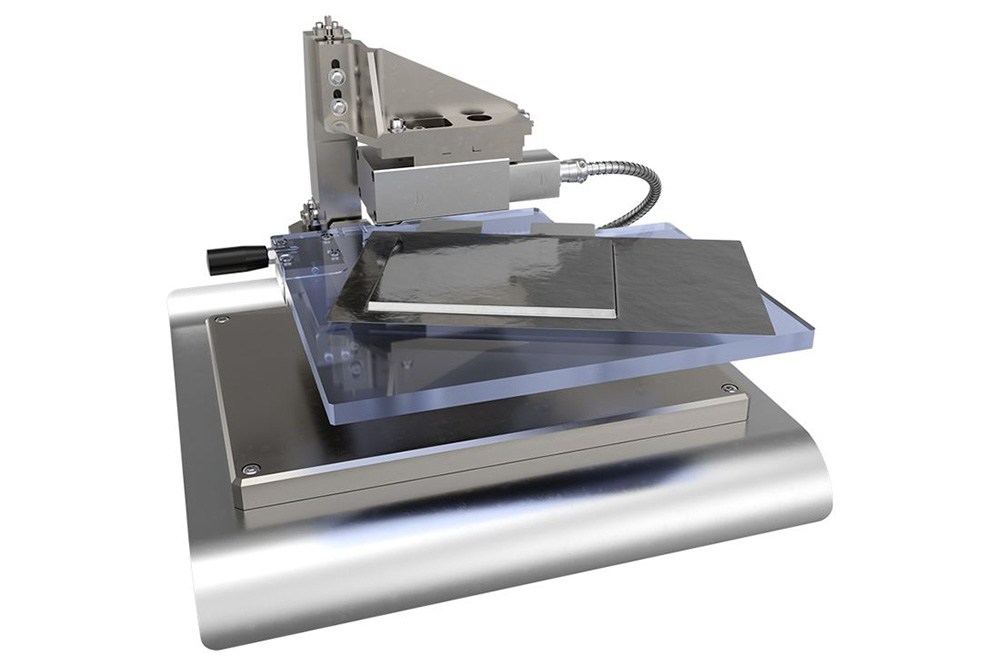

Marposs, a designer and producer of measurement, inspection and testing merchandise, has introduced a brand new system for checking the welding joints of pouch cell batteries inside the manufacturing course of, consisting of interferometric sensors and the corporate’s NCG (non-contact gauge) controller.

The system works by splitting gentle into two beams that journey completely different optical paths and are later mixed to provide interference, which might determine refractive modifications and floor irregularities.

Pouch cell batteries are usually sealed utilizing impulse or contact welding (warmth sealing), which fuses the plastic layers collectively. The thickness of this joint is a key indicator of the standard of the seal, and should be measured whereas the fabric continues to be mushy. Marposs says its system is ready to verify the thickness proper after the welding course of utilizing the non-contact interferometric know-how.

The answer can measure skinny exterior plastic layers beginning at 1 µm and accommodate thickness variations as a result of presence of the tabs in elements of the welding seam. It comes with a measuring snap with two interferometric sensors that allow the simultaneous measurement of the whole thickness of the welding seam and the thickness of the 2 exterior plastic layers. Every sensor has a measuring area of 900/1.8 mm and provides a repeatability vary inside 1 mm of the applying thickness.

Supply: Marposs

[ad_2]