[ad_1]

Exro Applied sciences is constructing a future wherein an EV’s motor, drive, gearing and AC charging system are built-in into one extremely compact and environment friendly system. Engineers are at all times on the lookout for cost-effective methods to get probably the most vary out of an electrical car’s battery pack. Exro Applied sciences is triangulating on an answer with three core ideas: motor management, battery charging and powertrain optimization. Exro’s patented Coil Driver know-how took dwelling the Gold within the 2022 Edison Finest New Product Awards in manufacturing, logistics and transportation. The unique concept has now launched its personal spin-off know-how that enabled quick AC charging, eliminating the car’s onboard charger and facilitating vehicle-to-everything (V2X) capabilities.

Exro’s latest companions embrace Neighborhood Motor Company, which is piloting Exro’s high-voltage Coil Driver in its Lightning eBus, and evTS, which is able to use Exro’s low-voltage Coil Driver beginning in 2023. Exro has innovation and manufacturing facilities in Calgary, Phoenix and Ann Arbor, and a rising listing of companions and merchandise.

Charged just lately chatted with Josh Sobil, Exro’s Chief Industrial Officer, to study extra in regards to the firm’s know-how, its historical past and its imaginative and prescient for the longer term.

Charged: Exro began with an concept for a novel motor management system. Are you able to inform us the way it works?

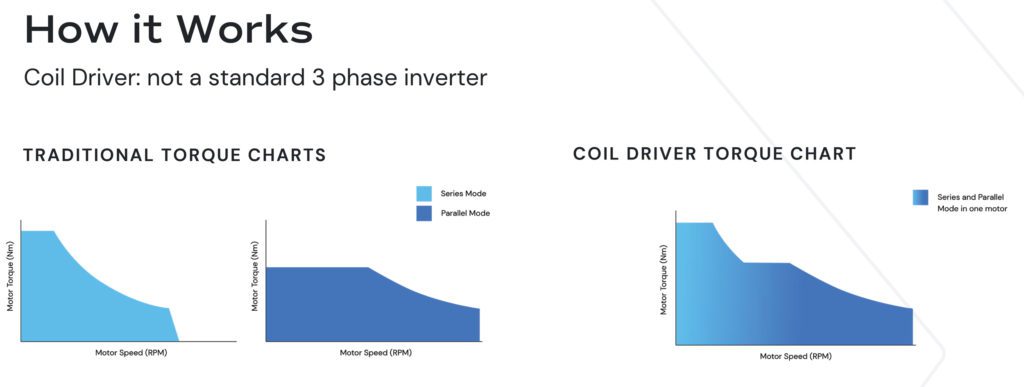

Josh Sobil: Electrical motors are designed to ship both excessive torque or excessive velocity, relying on the way in which wherein the coil windings are configured. Functions that want each torque and velocity often require both a motor/gearbox mixture or multiple motor, including weight, value and complexity to the system. Exro’s core know-how is a novel motor management system, the Coil Driver, wherein the motor coils are wound in order that they are often reconfigured on the fly to effectively present the requisite torque or velocity, with out the necessity for a gearbox or a number of motors.

You can begin the machine in a sequence configuration, which offers a excessive present density and a really excessive torque. Then it may swap to a parallel state of affairs, which reduces the impedance of the coils and delivers extra energy whereas sustaining the motor’s effectivity.

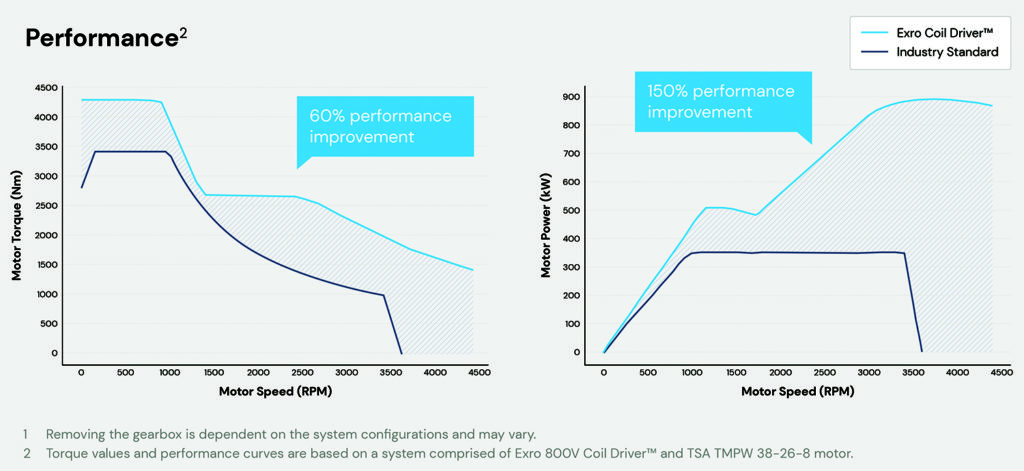

The idea behind the Coil Driver is the power to drive the machine in two completely different configurations. You can begin the machine in a sequence configuration, which offers a excessive present density and a really excessive torque. Then it may swap to a parallel state of affairs, which reduces the impedance of the coils and delivers extra energy whereas sustaining the motor’s effectivity. The important thing benefit is the power to develop that effectivity map or that torque envelope, and get extra out of the identical body, so we are able to cut back the machine’s value and enhance its efficiency. The Coil Driver offers the engineer one other choice to tweak the design of the powertrain and get extra out of the machine.

There are circumstances the place we use smaller machines to get the identical quantity of energy and torque that’s required out of a given drive cycle, or we do away with elements just like the two-speed gearbox in functions that solely want a low gear to supply 5 to 10 seconds of very excessive beginning torque. We see a number of that within the business car area. Any time you’ll be able to take away elements and enhance effectivity, it’s a bonus to our prospects [because] they will both cut back the scale of the battery or take away different elements that is perhaps extra pricey.

Charged: Can you are feeling the shift while you swap the topology of the drive, like shifting gears?

Josh Sobil:It shifts in about ten milliseconds. We’ve got seen somewhat kick, however in a business car or a automotive, it wouldn’t even register as a result of the inertia would simply soak up it. On a motorbike or one thing small, there is perhaps somewhat kick, however we are able to program it so that you don’t really feel it. That’s a part of our secret sauce—the power to change in a short time and not using a torque interruption, particularly in business car functions. Having a torque interruption is sort of an enormous deal since you’ve acquired a lot inertia to beat. Anytime you’re on a hill and also you interrupt the torque it’s simply extra work that you must do, and extra stress and pressure on the precise system. So, the quicker you’ll be able to swap, the extra advantageous it’s.

Charged: The place did the Coil Driver concept come from? What’s the historical past behind it?

Josh Sobil: It’s type of your traditional startup story. The founder, Jonathan Richie, was a storage inventor, as they are saying, with an curiosity in wind energy. He was the truth that windmills generated energy at varied torques and speeds, only some of which might be on the optimum setting. At one time, it’d solely be working at 85% effectivity, versus 96% effectivity at precisely the precise load. So he thought, “If I may change the circuit contained in the machine [on the fly] then perhaps I may get completely different working factors to have greater efficiencies [across the whole operating curve]. If I may begin to meld these collectively, then I may see an general enhance in generator effectivity.”

As a startup in a storage, the problem was breaking right into a wind era market that’s working with megawatt-level machines. Designing merchandise for that market was prohibitive from the beginning. That’s to not say that it’s not use case—I feel will probably be, however there was additionally an EV market alternative that was constructing. An EV motor has a profile the place, when you have a look at a machine’s torque curve after which plot all the working factors that an EV truly operates beneath, it virtually fills your complete torque map. So we decided that that is in all probability a extra accessible market, simply from a commercialization standpoint. For instance, we may design a hundred-kilowatt inverter for an off-highway software, which is rather a lot much less stringent than even an automotive software or a wind energy software. So there are methods to get into the EV market, though the obstacles to entry are completely huge. We’re seeking to our companions to assist convey us into the larger automotive sector.

Charged: There should be a cost-benefit evaluation that you just work by way of with the completely different functions, like off-highway or business vehicles. What’s the primary software that you just’re engaged on proper now?

Josh Sobil: We’re city and freeway functions, which require a really excessive peak effectivity throughout your complete working vary—what’s known as an effectivity island—and that’s precisely what the know-how does. So if the car is working at low velocity, we are able to ship the torque to get began, perhaps to climb a really steep incline. That may present a brand new route {that a} rubbish truck can take within the metropolis, enhancing the effectivity of the general operation. And there’s an growth of that curve in order that the effectivity is best at freeway speeds as effectively. That’s undoubtedly the place we see the Coil Driver shine.

We’re city and freeway functions, which require a really excessive peak effectivity throughout your complete working vary—what’s known as an effectivity island—and that’s precisely what the know-how does.

There are functions that require a number of torque down low, however in addition they want energy at freeway speeds. That’s a really typical trade-off in any electrical machine. A gearbox offers excessive torque, however it may’t enhance energy. So we’ve seen a number of curiosity within the off-highway sector, and even in bikes, which want a number of energy on the excessive finish, but additionally wish to be mild.

The powertrain is a key element of the car’s weight—the battery and the motor are going to be very heavy elements. If we are able to light-weight the motor and nonetheless ship the facility and torque, then it’s software. We’re additionally working with companions within the passenger automotive sector. By eradicating the onboard charger and integrating three-in-one configurations, we’re lowering each value and weight. And that’s what we’ve seen the OEMs wanting. While you present an effectivity profit, they’re going to ask, “How a lot smaller can I make my battery?” That’s the greenback issue that they’re going to use.

Battery charging

Charged: You talked about eradicating the onboard charger. How does Exro’s know-how have an effect on battery cost management?

Josh Sobil: That function was a byproduct of the way in which the topology was constructed up. What’s attention-grabbing is the power to do that with an AC frequency, so that you don’t want a DC provide to cost shortly. You probably have a really excessive steady energy you can ship by way of the powertrain, you’ll be able to cost at a significantly greater energy than what you may get out of a DC quick charger. It’s one thing that we’ve been testing and proving out, and we’re anticipating to launch it in our second era of drives. We’ve now acquired a patent pending for the power to cost by way of the Coil Driver.

All of our high-voltage merchandise can settle for this, so you might use it in a passenger car as effectively. We’ve demonstrated charging above 20 kW proper now, simply with the usual Coil Driver. As soon as we transfer to the upper powers, then we’ve got steady energy scores up into the a whole bunch of kilowatts, so that is one thing you might placed on a passenger automotive. You would want to take a look at the infrastructure and make sure that the plug was applicable, however it might exchange the EV’s onboard charger.

Successfully we’re utilizing the drive itself because the onboard charger. It’s a four-quadrant drive, so we are able to run energy in each instructions. The identical approach you’ll regenerate whilst you’re braking, you’ll be able to convert AC energy to DC energy by way of the drive.

Successfully we’re utilizing the drive itself because the onboard charger. It’s a four-quadrant drive, so we are able to run energy in each instructions. The identical approach you’ll regenerate whilst you’re braking, you’ll be able to convert AC energy to DC energy by way of the drive. And that’s essentially all we’re doing. An inductive element is required to do this, so we use the motor’s inductance.

Charged: Why doesn’t everybody design a motor drive that will also be used because the onboard charger?

Josh Sobil: Good query. Essentially, as a result of the motor would produce torque, so you’ll be able to’t use the machine until it produces no torque. Should you had been to use the present by way of a typical motor, it might naturally begin turning. With the Coil Driver, since we are able to management the person coils, we apply the present in an opposing vogue, so the torque cancels itself contained in the machine. It’s important to be certain that to chill the drive, clearly, since you’re going to have present and also you’re going to have losses, however these are the primary variations.

And I must also [point out that] there are others which have checked out doing this with a six-phase drive by opposing three of the phases. So we’re not the one ones that may do that, however it’s an added function to what we’ve been in a position to do with simply the topology of the drive itself and the way in which that we join it to the machine. We don’t change something within the drive, and essentially a drive can join as a rectifier in that very same approach, however it’s the way in which that we join that enables us to supply zero torque out of the machine. That’s a local benefit to the know-how that, in all honesty, we realized a bit after the very fact. We had been targeted on the torque envelope and effectivity after which we thought, “There’s dialogue on the market about utilizing the drive as a charger, so may we use this?” So we made positive it labored and a couple of 12 months in the past we utilized for the patent. Now it’s changing into a focus as a result of it’s an enormous cost-saving function.

Powertrain optimization

Exro affords engineering companies to assist its prospects design or modify motors to accommodate its Coil Driver know-how. The corporate offers a co-development platform to customise inverter controls that cut back the necessity for a number of motors and/or gearboxes and optimize battery utilization.

Charged: So while you name it a three-in-one system, what three elements are you referring to precisely?

Josh Sobil:The time period three-in-one system refers back to the drive, motor and gearing as an built-in drive unit. They’re often called e-axles or built-in drive models on the automotive facet. After which you’ll be able to think about how way more compact it’s with out the charger, so you are able to do all the things with that built-in drive system. That’s our imaginative and prescient—our roadmap for the longer term is actually round having the ability to combine all the things within the EV’s powertrain. Attempting to light-weight, downsize and make all the things extra compact at a system stage has a fascinating affect on value.

Charged: Suppose you’re speaking to a possible buyer and so they simply wish to enhance the effectivity of an electrical rubbish truck. As a basic instance, how would you estimate the potential effectivity beneficial properties together with your Coil Driver system?

Josh Sobil: What we’ve been simulating—and it clearly relies on the drive cycle somewhat bit—reveals that business vehicles are likely to have round a 3-4% vary enhance. Should you can take away 4% of a 200 kWh battery, at $135 a kilowatt-hour, then you definately’re saving roughly $1,000. Or you’ll be able to preserve the identical dimension battery and get 4% extra vary at no further value.

We’ll be beginning some real-world drive cycle testing this winter. We’re enthusiastic about that. It’s coming with certainly one of our companions for an e-axle on a business truck.

Charged: So, you might have the {custom} energy electronics design and also you couple that with a custom-wound motor. Will you at all times provide that mixture as a package deal?

Josh Sobil: Relying on the client, sure, we’ll promote it as a system. Some prospects will design their very own machine and we are going to couple the inverter to their motor. Essentially, we’re not a motor producer, however the know-how requires that in some circumstances we’ve got a machine to promote. We’re not altering the magnetic design of the machine—we’re altering the way in which we connect with its coil groupings. It’s extra of a mechanical interface for the cables. The drive itself simply replaces a typical inverter, however what you’ll see are twelve connections—4 per section—going into the machine.

Charged: The elemental {hardware} distinction is that you’ve got an inverter with much more switches than a typical one, proper?

Josh Sobil: Precisely. We’re nonetheless utilizing customary switching gadgets—the topology of the drive is what’s completely different. The circuit is not like every other drive that’s on the market as a result of we’re driving particular person coils, so it doesn’t seem like a typical three-phase drive. However we nonetheless use silicon carbide (SiC) gadgets. In our high-voltage inverter, we’re utilizing a typical PCB design and manufacturing strategies. Finally, we’ll get to a naked die development on the drives.

The circuit is not like every other drive that’s on the market as a result of we’re driving particular person coils, so it doesn’t seem like a typical three-phase drive.

Charged: What section of commercialization are you in now? What are the subsequent steps for Exro?

Josh Sobil: Proper now, we’re in our launch section beginning in ‘23. We’ve got some early companions which have positioned orders for tools. They wish to see samples on the finish of this 12 months to allow them to begin to validate into the subsequent 12 months. We’re constructing a drive manufacturing facility in Calgary and plan to supply drives for business and off-highway functions by the third or fourth quarter of subsequent 12 months.

Charged: Do you might have every other merchandise along with Coil Driver?

Josh Sobil: Essentially, the corporate is targeted, obsessed and keen about energy electronics. We’re additionally engaged on methods to optimize energy on the battery facet. We’ve developed a battery management system that manages particular person cells, similar to managing particular person coils, so it’s taking that granular philosophy and transferring it over to the storage facet. It’s in our R&D pipeline, and we’re going by way of the UL approval course of on that storage unit.

This text appeared in Situation 62: Oct-Dec 2022 – Subscribe now.

[ad_2]