[ad_1]

Sponsored by ANSYS.

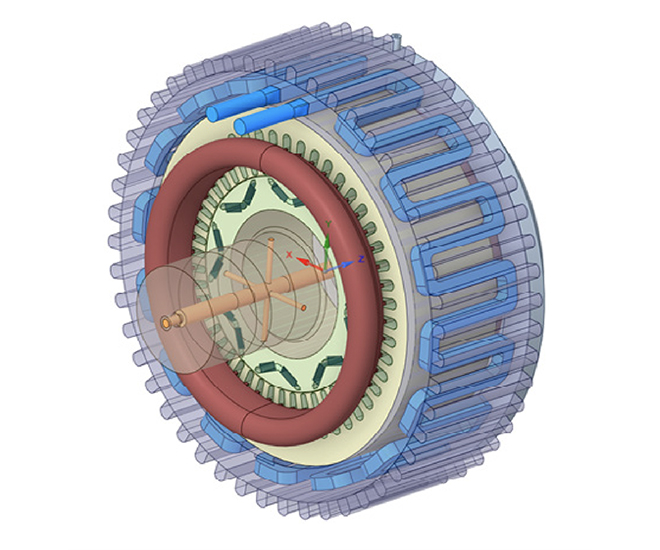

EV designers should tackle an more and more advanced matrix of engineering objectives on tightening timelines. Optimized system design requires analysis of many alternative ideas, topologies, and digital interactions throughout disciplines. Contemplating the traction motor alone, there are a number of design selections that influence the operate of the complete car. Engineers used to carry out electromagnetic evaluation in bits and items utilizing their very own calculations and applications, and, for a very long time, that was an acceptable resolution. Right now, engineers want simulation and common prototyping all through the design cycle. Implementing simulation workflows can enhance energy density, vitality effectivity, and operational life whereas assembly design necessities, trade requirements, and security laws.

Find out how simulation and optimization strategies can be utilized to handle system-level multiphysics complexities to condense design cycles of high-performance electrical traction motors. This whitepaper examines motor varieties, winding expertise choice for PMM, and cooling varieties plus key expertise issues.

Obtain the complete whitepaper from ANSYS

[ad_2]