[ad_1]

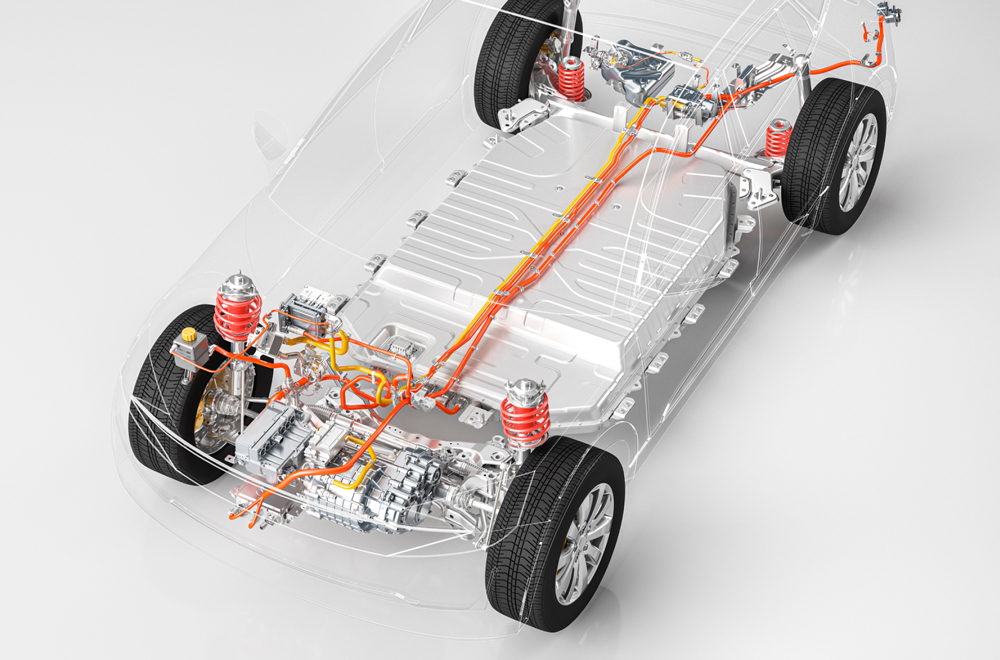

Battery administration programs (BMS)—the digital brains that displays and maintains lithium ion battery packs—are important for the protected and environment friendly operation of the batteries powering quite a lot of purposes, together with electrical autos. The expansion of electrical automobile expertise is pushed by the need for lowered emissions, quieter and cheaper autos, superior driver help programs and improved consolation and comfort. Full acceptance of electrical autos relies on their capability to reliably journey lengthy distances and scale back “vary nervousness,” which may be achieved partly by a battery administration system that enables the automobile to function extra effectively.

Battery administration programs present the automobile with real-time decision-making, diagnostics, and anticipatory management of each watt of energy demand all through the automobile. Knowledge acquisition happens through sensors that monitor electrical, security, and thermal subsystems and is transferred by communication community cables to the BMS interface, which in flip gives data on automobile efficiency and vary to the operator.

Battery packs make the most of three major wiring architectures. The primary makes use of a flat, versatile printed circuit with connectors and a centralized module controller. The second is a centralized module controller that makes use of discrete wires as a substitute of flex circuits. The third is a discrete wire with a decentralized module controller on every battery cell, which is individually managed and linked along with cable. Versatile printed circuits are much less complicated, whereas discrete wires with centralized and decentralized module controllers require extra complicated wiring options. Wire-to-board and FPC-to-board connectors are thought of automotive-grade connector options.

Amphenol affords quite a lot of wire-to-board programs designed to be extremely vibration resistant, together with a major latch and terminal and connector place assurance together with a variety of thicknesses, working temperatures, waterproof capabilities and positions. Their FPC-to-board programs are USCAR vibration and shock appropriate and supply simpler meeting, much less weight and are less expensive in comparison with discrete wire options.

Temperature monitoring

The power to observe and regulate the temperature of lithium ion batteries is important for his or her operation. Cells carry out greatest at a temperature vary of about 10°C to 60°C, however the course of concerned in charging and discharging lithium ion batteries generates warmth. If the temperature is just too low when charging, dendrites can develop and trigger everlasting harm to the cells, whereas greater temperatures allow extra speedy charging however can sacrifice cell life. Thermal administration management is required to delay the lifetime of the battery pack, particularly in massive arrays which may have as much as 4,000 cells in a system.

Sensors are important to managing battery system temperatures. Elements akin to thermocouples, resistance temperature units and adverse temperature coefficient thermistors can immediately measure temperatures, whereas infrared sensing is a non-contact choice. Most industrial and transportation controls use the highly-sensitive thermistor temperature sensing expertise. Thermistor sensors may be floor mount or lead wire designed and positioned on flex circuits, epoxy potted, overmolded or place in probe geometries.

On this electrically noisy surroundings of that features inverters and transformers, sensors want to face up to electromagnetic noise, which might induce present on sensor wires. With the rising complexity of electrical programs and the density of digital parts in trendy autos, typical adverse temperature coefficient thermistors are weak to stray electromagnetic interference, which might trigger self-heating. Conventional options akin to utilizing a twisted pair wire meeting can turn out to be expensive, so Amphenol has applied a filter capacitor expertise built-in with the thermistor that makes use of a radio frequency decoupling perform, which gives safety towards electromagnetic interference on the element stage.

In terms of coolant and refrigerant temperature sensors, non-contact infrared temperature sensing is usually used. This answer works for prime voltage purposes akin to charger-to-wire and interconnects and inside enclosures. Amphenol’s infrared-based thermal monitoring answer meets IEC 60664 clearance necessities and boasts a 20-millisecond time response.

The small-scale residential storage market, in addition to large-scale “behind the meter” storage markets, are rising quickly. On the residential stage, passive cooling, convection cooling and liquid cooling strategies are used, requiring temperature sensor suggestions on cell surfaces in addition to the monitoring of coolant temperature. For big-scale electrical stationary storage programs, pressured air convection cooling and liquid cooling are used. This requires extra strong monitoring, together with the temperatures of the enclosure and battery busbar, in addition to humidity, water intrusion/coolant breach, non-contact temperature monitoring of excessive voltage parts, and thermal runaway detection. Ambient air temperature and rain sensors could also be wanted as effectively for purposes akin to climate stations

Liquid and thermal runaway monitoring and detection

Whereas temperature monitoring is a crucial ingredient to protected and environment friendly lithium ion battery administration, there are different parts that require early detection. Coolant leakage and water intrusion could cause important points, together with accelerated corrosion and thermal runaway. Current recollects at GM and BYD resulting from liquid intrusion spotlight the significance of early detection of any water throughout the system.

Amphenol’s coolant breach/water intrusion detection sensor is beneficial for each coolant breach and water intrusion detection and might establish as little as 3mm of conductive liquid within the battery enclosure. The sensor is immune to condensing occasions and is usually deployed in traction battery packs, stationary storage programs and chargers.

Thermal runaway in lithium ion batteries is one other problem that may be mitigated with early detection. Though inside combustion engine automobile fires happen as soon as each three minutes in the USA and electrical autos have a 90 p.c decrease chance of experiencing a fireplace incident than ICE autos, battery malfunctions nonetheless make the headlines—and supply distinctive challenges to first responders.

In electrical autos, battery packs are sometimes tough to entry, and thermal runaway temperatures can exceed 1,000°C whereas emitting hazardous and flammable gases that enhance the chance for explosion. Gases, particulates and water vapor from the battery, mixed with excessive voltage programs, can enhance the chance of arc discharge. Lithium ion battery fires are lengthy period occasions because the batteries present their very own oxygen to assist combustion and broken cells could cause reignition. It may be tough to evaluate the state of the battery cell or pack and decide the top of the occasion, and combating these fires requires coaching, new processes and new instruments.

Figuring out a possible thermal runaway requires an clever sensor able to shortly detecting even a single cell venting inside a big array. Amphenol’s Sturdy Early Detection of Thermal Runaway (REDTR) answer makes use of physics-based gasoline detection of preliminary cell venting utilizing hydrogen and carbon dioxide sensors and is able to working independently of the BMS to permit the BMS to “sleep straightforward” whereas REDTR maintains a steady watch over each cell within the pack. With a small package deal measurement and a design lifetime of greater than 20 years, REDTR will preserve vigilance over battery security from manufacturing to recycling.

Amphenol affords quite a lot of temperature sensors, stress sensors, present sensors, place and pace sensors, together with quite a lot of customized units for batteries, thermal administration programs, motors and gasoline cell applied sciences, making them a one-stop store for sensors. Amphenol’s portfolio of sensors that allow the early detection of thermal runaway in addition to coolant breaching water intrusion detection, EMC-immune temperature sensors, noncontact high-voltage element temperature sensors and thermal administration purposes. Amphenol’s deep understanding of battery habits additionally makes them one of many world’s largest suppliers of cell connection programs (CCS) for battery programs, serving to sense, talk and transfer power for an extended, sturdy battery life.

Sponsored by TTI and Amphenol

[ad_2]